The Process of Explosive Welding

The Introduction of Explosive Welding Recombination. What is clad in Explosive Welding?Metal composite materials processing methods are divided into: direct rolling composite method, explosive bonding method and explosive + rolling combined technology.

Explosion + rolling combined technology: the use of Explosive Welding technology to prepare blanks, and then rolling to the required specifications, this technology is suitable for the production of thinner large-surface composite panels.

Detonator detonates explosives to produce high pressure

Drive the high-speed tilting movement of the composite board to collide with the substrate

Form a jet for self-cleaning process

High-voltage pulse load makes the metallurgical combination of the composite board and the substrate

Explosive compound dynamic process. What is Explosive Welding used for?

Schematic diagram of Explosive Welding process

History of explosive welding technology. How does explosive welding work?

The American L.R.Carl discovered explosive welding in 1944;

In the 1960s, American V.Philipchuk used it for the first time in industrial engineering;

Then Britain, Russia, Germany, Japan, France and other countries have successively carried out research work;

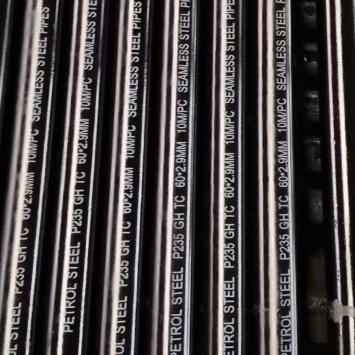

China has basically started research at the same time as western countries, and PETROL STEEL CO., LTD is also one of the companies researching explosive compounding (using our explosive plant and explosive welding technology).

Main applications of explosive composite materials. What is cladding plate?

Chemical industry-reactor, reactor;

Petrochemical industry-hydrogenation catalyst tower, distillation tower, composite pipeline joints;

Power industry-condenser tube sheet, chimney steel lining board, wire transition joint;

Devices and equipment in the desalination industry;

Pressurizers, desalination devices, and reactor heat exchangers in the nuclear energy industry;

Satellite transition joints and aircraft skin materials for the aerospace industry.

The current domestic production of composite panels is about 120,000 tons/year, of which titanium steel composite plates are about 30,000 tons.

The Advantages of explosive welding:

Metals with the different coefficients of thermal expansion, metals with strong activity, and materials that cannot be welded by conventional welding methods, such as aluminum-steel, copper-steel, titanium-steel, zirconium-steel and other metal combinations using explosive welding (or composite) methods can achieve.

explosive cladding has high bonding strength. Because explosive cladding is completed in microseconds under high temperature and high pressure, there are fewer phenomena such as diffusion, inclusion, and crystal shape change on the bonding surface. Therefore, the bonding strength of explosive cladding is often lower than that of the lower metal in the welded metal. High, the welding interface maintains a certain degree of toughness. It is a solid phase welding method. Because the explosive welding time is extremely short, the chemical composition and mechanical properties of the material are not changed before and after welding.

Wide range of size and thickness ratio. What is explosion welding?

explosive cladding can be used for plate welding, as well as for inner cladding welding and outer cladding welding of pipes to prepare composite pipes and bars.

Unlike friction welding and diffusion welding, explosive welding achieves interatomic bonding, with high bonding strength and a wave-like bonding interface.

Explosively welded plates, tubes, bars which have excellent subsequent processing performance, such as rolling, stamping, rolling, turning, milling, planing, boring, etc.

English

English Chinese

Chinese