Description

What is the function of the Air Cooling Tower?

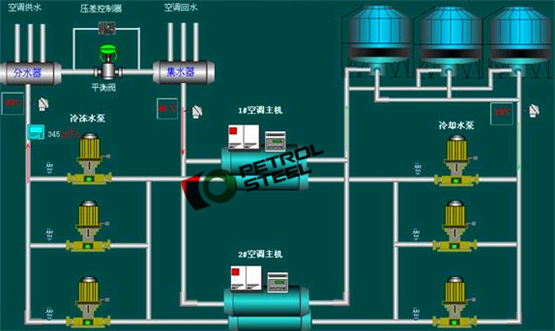

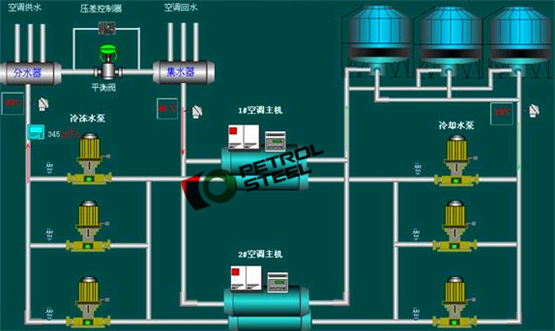

The Air Cooling Tower is a device that uses water as a circulating coolant to absorb heat from a system and discharge it into the atmosphere to reduce the temperature of the water.

How does the Cooling Towers Work? What's the working Principles of the Cooling Towers?

Its cooling is to use water and air to flow in contact and exchange heat and cold to produce steam. The volatilization of the steam takes away heat to achieve evaporation and heat dissipation. The principle of convective heat transfer and radiation heat transfer is an evaporative heat dissipation device that reduces the water temperature by dissipating the waste heat generated in the industry or in refrigeration and air conditioning to ensure the normal operation of the system. The device is generally barrel-shaped, so it is called a cooling tower.

How many types of Air Cooling Towers are there?

According to the ventilation method, there are 3 types of

1. Natural ventilation cooling tower;

2. Mechanical ventilation cooling tower;

3. Mixed ventilation cooling tower [3]

According to the contact method of water and air:

1. Wet cooling tower;

2. Dry cooling tower;

3. Dry and wet cooling tower.

According to the flow direction of hot water and air:

1. Counter-flow cooling tower;

2. Cross-flow (direct AC) cooling tower;

3. Francis-flow cooling tower

According to the application area:

1. Industrial cooling tower;

2. Air conditioning cooling tower.

According to the noise level:

1. Ordinary cooling tower;

2. Low noise cooling tower;

3. Ultra low noise cooling tower;

4. Ultra-quiet cooling tower.

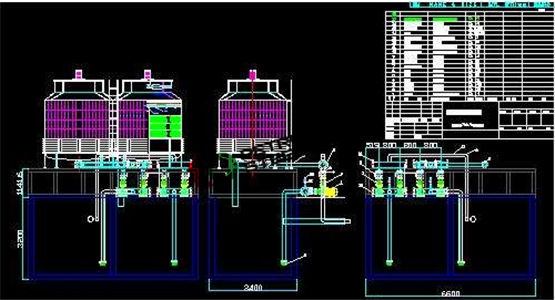

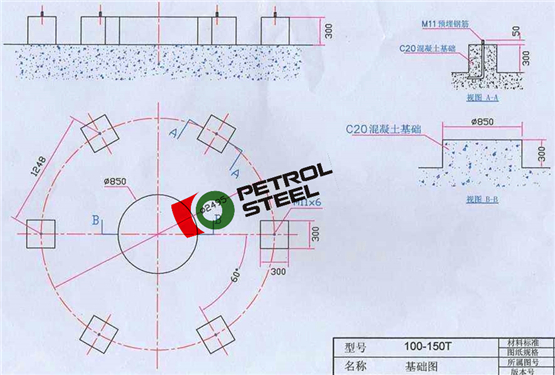

According to the shape:

1. Circular cooling tower:

2. Square cooling tower.

According to whether water and air are in direct contact:

1. Open cooling tower;

2. Closed cooling tower (also known as closed cooling tower, closed cooling tower).

Other types of cooling towers, such as jet cooling towers, fanless cooling towers, etc.

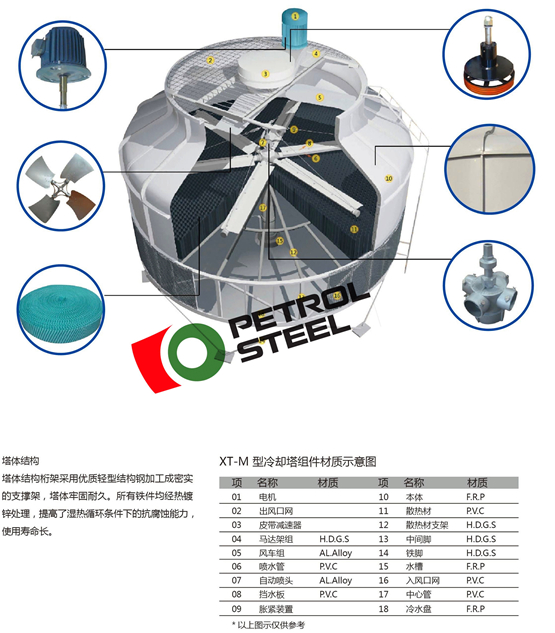

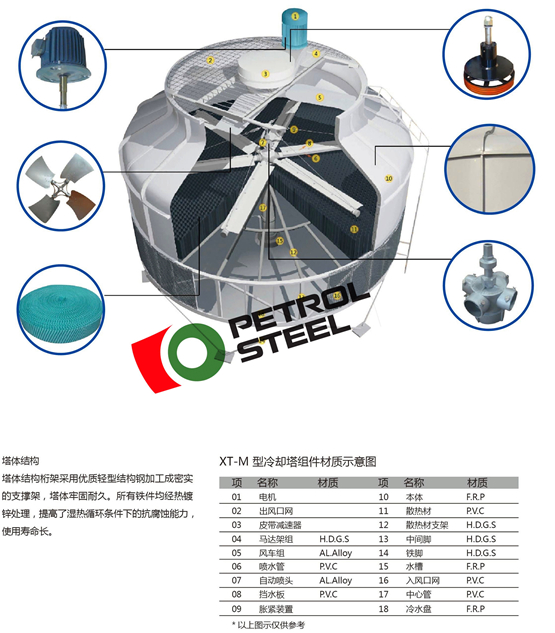

What are the conventional and vulnerable parts of the cooling tower?

1. Special motor power for cooling tower: 0.25kw-30kw.

2. Specification of belt reducer for cooling tower: 150T/h-1000T/h.

3. Specification of planetary reducer for cooling tower: 3.0KW-30KW.

4. Specification of aluminum alloy fan for cooling tower: 600mm-600000mm.

5. Cooling tower packing: PVC diagonal corrugated packing specifications: 125, 200, 230, 250, 300. Inclined corrugated square tower packing: 1000mmX500MM, 1200MMX500MM.

6. Point corrugated square tower packing: specifications: 1000mmX500MM, 1200MMX500MM.

7. Special water collector for cooling tower: Material: polyvinyl chloride (PVC), glass fiber reinforced plastic (FRP).

8. Special windshield for cooling tower: Specifications: 50T/h-1000T/h.

Where can I buy high quality and cheap cooling towers?

One of the top best brand PETROL STEEL CO., LTD can satisfy your requirement and can supply 7*24h free services for you.

Equipped with a condenser, why the thermal power plants still need to install the cooling towers?

Cooling tower refers to a large piece of equipment above the ground. The condenser refers to the equipment in a tower-shaped building.

What are the differences and relations between the cooling tower and the condenser?

The water is lost due to evaporation, and evaporation increases the salinity of the circulating cooling water. In order to stabilize the water quality, part of the water with higher salinity must be drained; the wind will also cause the loss of water dispersion. There must be enough new water to be replenished continuously. Therefore, the wet cooling tower needs a water source for supplying water.

How should I descale the air cooler tower?

What are the best methods, steps, and plans for cleaning Air Cooling Towers?

For a long time, traditional cleaning methods such as mechanical methods (scraping, brushing), high-pressure water, chemical cleaning (pickling), etc. have encountered many problems when cleaning equipment: they cannot completely remove deposits such as scale, and acid causes corrosion to equipment and forms loopholes. , The residual acid will cause secondary corrosion or under-scaling corrosion to the material, which will eventually lead to the replacement of equipment. In addition, the cleaning waste liquid is toxic and requires a lot of money for wastewater treatment.

What brand of cleaning agent is used to clean the cooling tower? What brand of cooling tower descaling agent is easy to use?

The Air Cooling Tower is a device that uses water as a circulating coolant to absorb heat from a system and discharge it into the atmosphere to reduce the temperature of the water.

How does the Cooling Towers Work? What's the working Principles of the Cooling Towers?

Its cooling is to use water and air to flow in contact and exchange heat and cold to produce steam. The volatilization of the steam takes away heat to achieve evaporation and heat dissipation. The principle of convective heat transfer and radiation heat transfer is an evaporative heat dissipation device that reduces the water temperature by dissipating the waste heat generated in the industry or in refrigeration and air conditioning to ensure the normal operation of the system. The device is generally barrel-shaped, so it is called a cooling tower.

How many types of Air Cooling Towers are there?

According to the ventilation method, there are 3 types of

1. Natural ventilation cooling tower;

2. Mechanical ventilation cooling tower;

3. Mixed ventilation cooling tower [3]

According to the contact method of water and air:

1. Wet cooling tower;

2. Dry cooling tower;

3. Dry and wet cooling tower.

According to the flow direction of hot water and air:

1. Counter-flow cooling tower;

2. Cross-flow (direct AC) cooling tower;

3. Francis-flow cooling tower

According to the application area:

1. Industrial cooling tower;

2. Air conditioning cooling tower.

According to the noise level:

1. Ordinary cooling tower;

2. Low noise cooling tower;

3. Ultra low noise cooling tower;

4. Ultra-quiet cooling tower.

According to the shape:

1. Circular cooling tower:

2. Square cooling tower.

According to whether water and air are in direct contact:

1. Open cooling tower;

2. Closed cooling tower (also known as closed cooling tower, closed cooling tower).

Other types of cooling towers, such as jet cooling towers, fanless cooling towers, etc.

What are the conventional and vulnerable parts of the cooling tower?

1. Special motor power for cooling tower: 0.25kw-30kw.

2. Specification of belt reducer for cooling tower: 150T/h-1000T/h.

3. Specification of planetary reducer for cooling tower: 3.0KW-30KW.

4. Specification of aluminum alloy fan for cooling tower: 600mm-600000mm.

5. Cooling tower packing: PVC diagonal corrugated packing specifications: 125, 200, 230, 250, 300. Inclined corrugated square tower packing: 1000mmX500MM, 1200MMX500MM.

6. Point corrugated square tower packing: specifications: 1000mmX500MM, 1200MMX500MM.

7. Special water collector for cooling tower: Material: polyvinyl chloride (PVC), glass fiber reinforced plastic (FRP).

8. Special windshield for cooling tower: Specifications: 50T/h-1000T/h.

Where can I buy high quality and cheap cooling towers?

One of the top best brand PETROL STEEL CO., LTD can satisfy your requirement and can supply 7*24h free services for you.

Equipped with a condenser, why the thermal power plants still need to install the cooling towers?

Cooling tower refers to a large piece of equipment above the ground. The condenser refers to the equipment in a tower-shaped building.

What are the differences and relations between the cooling tower and the condenser?

The water is lost due to evaporation, and evaporation increases the salinity of the circulating cooling water. In order to stabilize the water quality, part of the water with higher salinity must be drained; the wind will also cause the loss of water dispersion. There must be enough new water to be replenished continuously. Therefore, the wet cooling tower needs a water source for supplying water.

How should I descale the air cooler tower?

What are the best methods, steps, and plans for cleaning Air Cooling Towers?

For a long time, traditional cleaning methods such as mechanical methods (scraping, brushing), high-pressure water, chemical cleaning (pickling), etc. have encountered many problems when cleaning equipment: they cannot completely remove deposits such as scale, and acid causes corrosion to equipment and forms loopholes. , The residual acid will cause secondary corrosion or under-scaling corrosion to the material, which will eventually lead to the replacement of equipment. In addition, the cleaning waste liquid is toxic and requires a lot of money for wastewater treatment.

What brand of cleaning agent is used to clean the cooling tower? What brand of cooling tower descaling agent is easy to use?

In response to the above situation, domestic and foreign efforts have been made to develop cleaning agents that are less corrosive to metals, and PESCO cleaning agents have been successfully developed. It has the characteristics of high efficiency, environmental protection, safety, and non-corrosion. It not only has a good cleaning effect but also has no corrosion to the equipment, which can ensure the long-term use of the cooling tower.

For more info and price of Air Cooling Tower, please contact us freely, you will have instant feedback

Tel/Fax: +86 10 8599 9168

Cel/Whatsapp/Wechat: 0086 159 0035 7871

Email: sales@petrolsteel.com, jackywinn@foxmail.com

English

English Chinese

Chinese